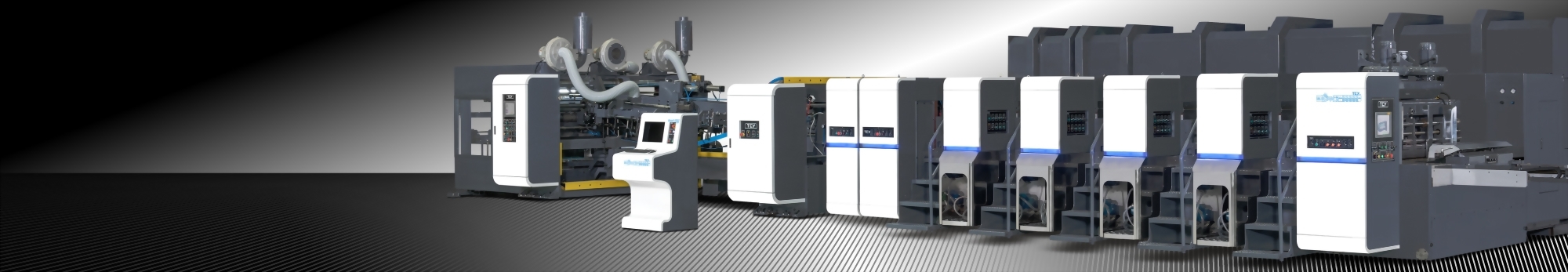

QSS Series Wet-End

Machine Size: 1800mm and 2500mm

Machine Speed: 250 MPM

QSS 300 model:

Machine Size: 1800mm and 2500mm

Machine Speed: 300 MPM

QSS 350 model:

Machine Size: 1800mm and 2500mm

Machine Speed: 350 MPM

Specifications

General Specifications

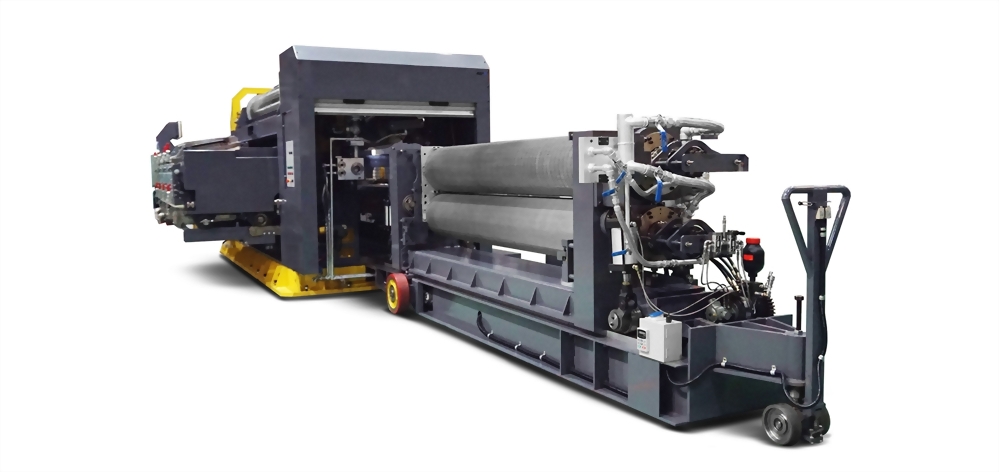

SINGLE FACER (MODEL: BSF-N)

• Blowing type for positive pressure fingerless design by turbo blower for any size of paper.

• Flute type: A, B, C or E flutes.

• Corrugating rolls locate on the base of the machine with the pressure roll being on top of them for lowing down the gravity of the machine and reducing the vibration of the machine to allow the perfect stability at any speed.

• Corrugating roll with cartridge device for quick roll change within 15 minutes.

• Main drive by AC Inverter motor included with timing belt to drive without gear box.

• Pressure roll Size: φ 450mm

• Upper corrugating roll Size: φ 408mm

• Lower corrugating roll Size: φ 408mm

• Automatic glue gap and glue dam control via setting by integrated computer system with glue roll auto idle device preventing glue dried on the surface of the glue roll while stopping the machine.

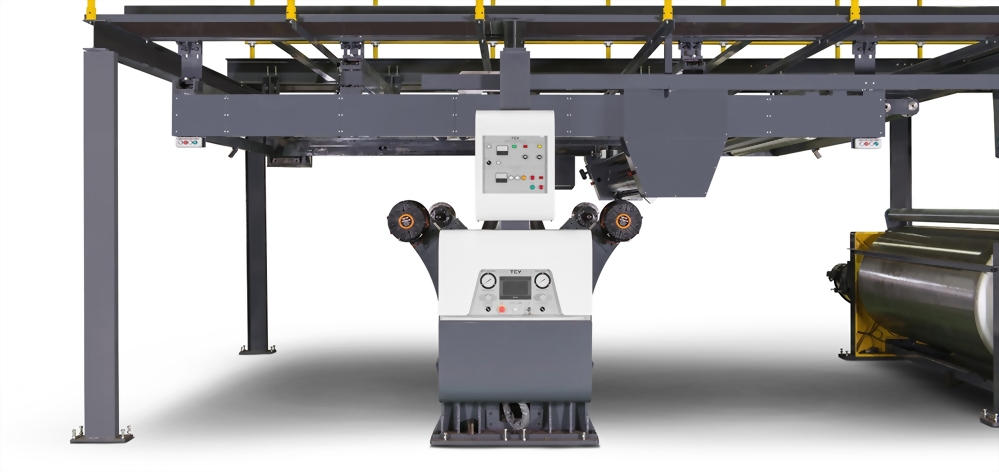

MILL ROLL STAND (MODEL:MS4-N)

• Working paper diameter : max. 1500mm, min. 330mm.

• Two pairs of swing arm can clamp and lift two paper rolls by hydraulic cylinder.

• Paper tension is manual adjusting pneumatic disk brake by pressure regulator.

• In case the pressure control of pneumatic brake links with auto splicer, paper tension will be automatic control.

• Maximum paper loading weight 3000kgs.

• Optional - “RENOVA” brake of multi-layer brake with cooling fan.

• Optional – expansion chuck 3”& 4”

• Optional – Infrared laser paper roll alignment system.

AUTO SPLICER (MODEL:SP100-MJQ)

• Maximum splicing speed: 300 m/min (line speed)

• Automatic tension control for paper by PLC to obtain reliable splicing.

• Automatic splicing to new paper while existing paper comes off paper tube.

• Splicing width is 40 mm of adhesive tapes, cutting from edge to edge for zero tail

• Cutting paper by serrated knife through pneumatic cylinder.

• Splice unit moves to right / left side for paper change and splicing

• Auto tension: Use magnetic powder clutch and PLC digital tension control system to ensure paper keep tension while production.

PREHEATER (MODEL:LPH-N ; 2PH-N ; 3LPH-N)

• Diameter of preheating drum:

750 or 900 mm for Preconditioner (2PH).

900 or 1100mm for Preheater (LPH & 3LPH)

• Preheating drum with delicate finishing surface.

• Manual brake equips on the shaft-end of preheating drum for free rotation or fixation.

• Preheating drum equips one stationary web guide roll and one motorized web guide roll for preheating area adjustment.

• Optional - automatic wrap angle control system and independent motor driving device for preheating drum.

• Optional – two guide roll system

• Optional – paper expansion roll

• Optional – temperature display system

BRIDGE (MODEL:FS-N)

• Take up belt device and transportation belt for accumulated web.

GLUE UNIT (MODEL:2GL-N)

• Motorized adjustment for web guider with preset digital counter on bottom control panel.

• Web guider can adjust for centering both upper webs to align with lower liner paper.

• Application roll driven by individual inverter motor. When the machine stops run, the application roll will be idle run to avoid glue conglutination.

• Each web equips with one fixed preheating drum Dia. 400 mm.

• Auto adjusting glue gap and Auto glue dam via HMI setting and integrated by computer system.

•Optional- “Contact bar” I/O ride roll.

DOUBLE FACER (MODEL:CDB-N)

• Steam heating plate made by high grade cast iron, the surface through precision machinery grinding and hard chrome plated for high abrasive resistance.

• Hydraulic cylinder with stroke control for weight rolls lowering and lifting. The setting height for specified flute of single wall and double wall is selected by integrated computer system and micro adjustment with display to meet with the correspondent thickness of substance paper.

• Tension of upper canvas belt stretched by hydraulic cylinder and lower belt stretched by manual adjustment.

• Surface of belting drum covered with anti-slip rubber.

• Each 6 piece of steam heating plate in a section with thermocouple and temperature display for steam heating control.

• Automatic and pneumatic constant upper belt tightener

•Automatic upper belt alignment device.

• Optional- “Thermo Bar”

• Optional water spray device