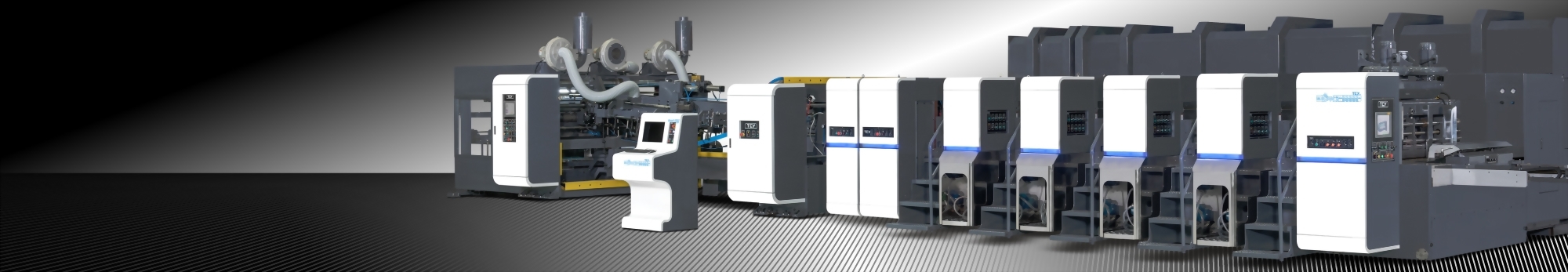

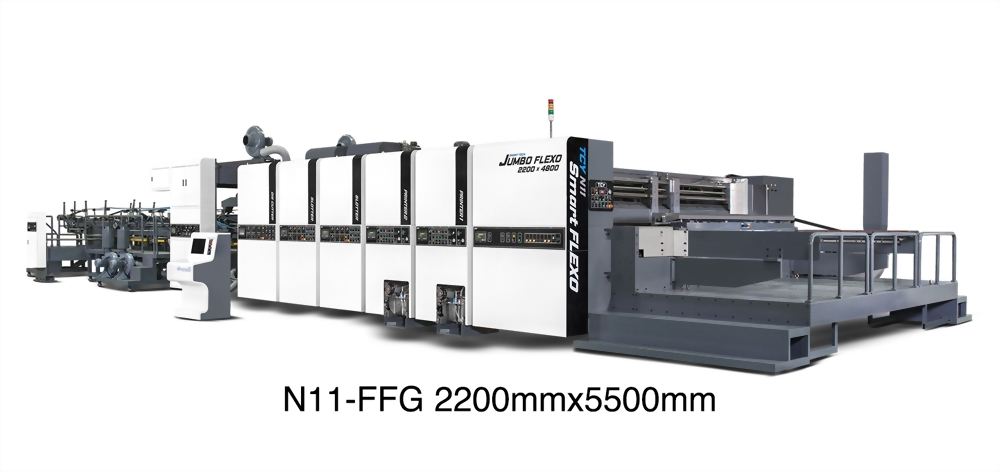

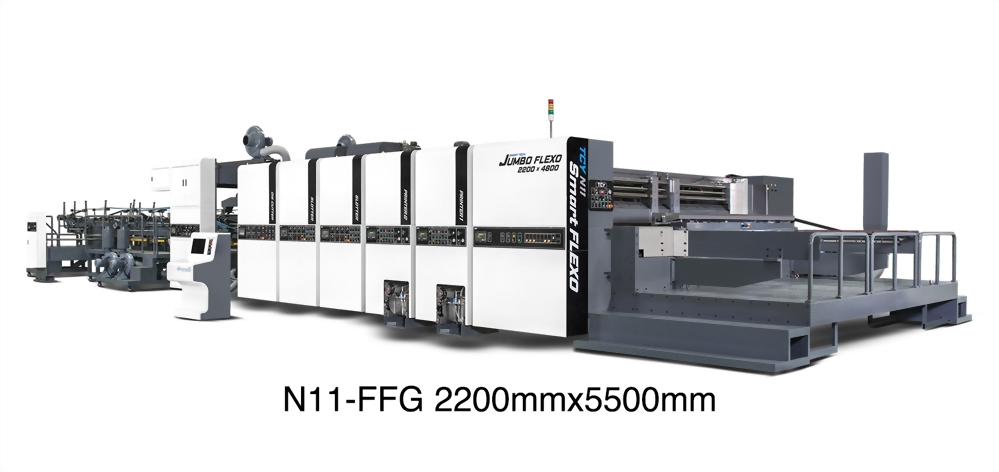

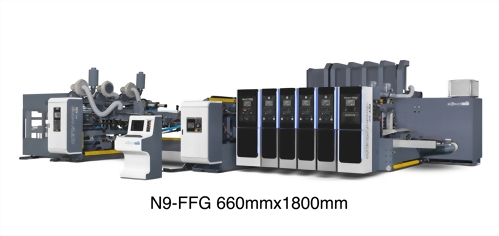

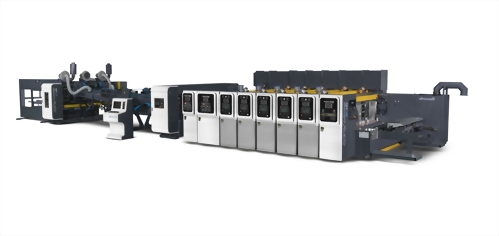

N11-FFG 2200mmx5500mm

2200mm x 4100mm ~ 5500mm

Max. Production Speed:

6,000 sheets/hr

Specifications

General Specifications

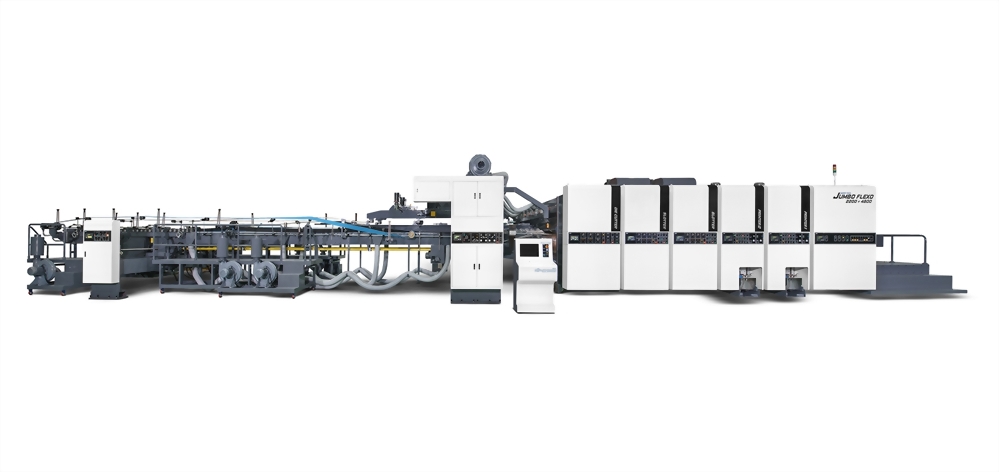

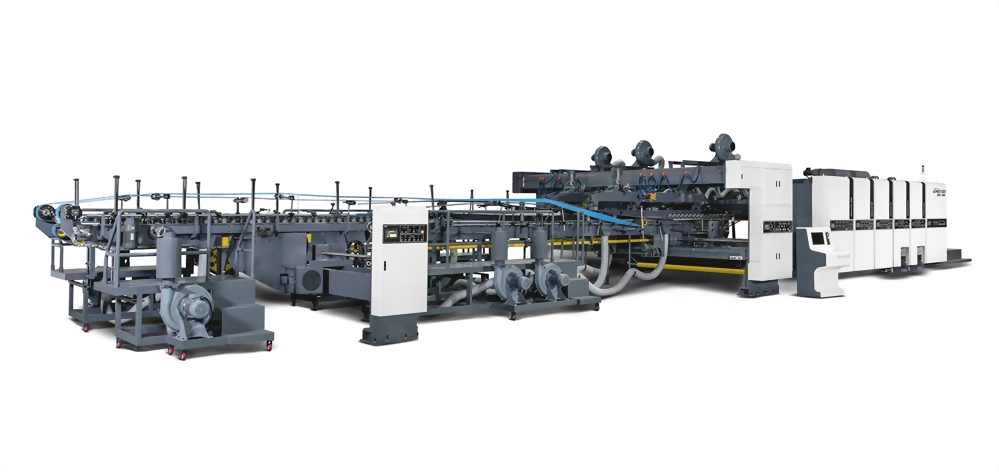

The new exterior streamlined shape design appearance the scientific and technology sense with the impressed vision.

By reducing the multi-function buttons and simplify the steps of order setting to make the machine friendly use and easy set up to increase your productivities.

Powerful N Series Smart-Tech system provides many convenient functions such like maintenance reminder system, error troubleshooting system, efficiency status, driver monitor…etc.

The new generation of the program can easily allow operators to understand the error code and troubleshooting. And easily scheduling the maintenance and spare parts life control.

FEEDING SECTION

• SUN lead edge feeder with accurate feeding for different flutes and warped sheets.

• Available for skip feed and feed interrupt.

• Auto zero-set for feeding position with one push button.

• Non back- lash transmission gear system.

• All gap adjustment via eccentric device with corresponding scale.

• Frequency inverter drive with variable suction control.

PRINTING SECTION

• Bottom print.

• Highly accurate printing registration.

• Chrome plated anilox roll.

• Rubber roll system as standard.

• Auto zero- set for printing position with one push button.

• Programming auto wash ink system.

DUAL UNITS SLOTTER CREASER SECTION

• Separate dual units design for easy maintenance.

• Each unit equipped one slotting shaft and one creasing shaft.

• Heavy duty design for large and strong box use.

• Auto zero- set for slotting knife with one push button.

• Pre-set one order function with auto positioning of slot knives for box panel.

• Central yoke head moveable.

DIE CUTTER SECTION

• Hydraulic oscillation movement for anvil drum to prolong anvil life time.

• Hydraulic oscillation movement to prolong anvil life time.

• Auto zero- set for die cutting position with one push button.

• Optional- Dicar “Equalizer”.

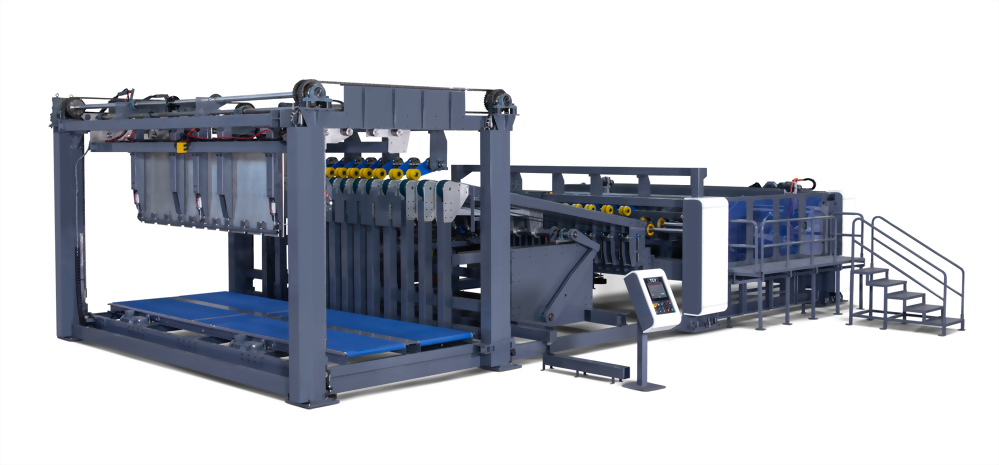

UP FOLDER GLUER

• Bottom suction belt with up folding for high performance.

• Use PU crushless wheel holding sheet for front folding section.

• Independent drive for side guiding wheel tracking box folded edge for accurate flap gap.

• Frequency inverter drive control system.

• Use “VALCO” Flexoseal system.

• Optional- Automatic stitcher.

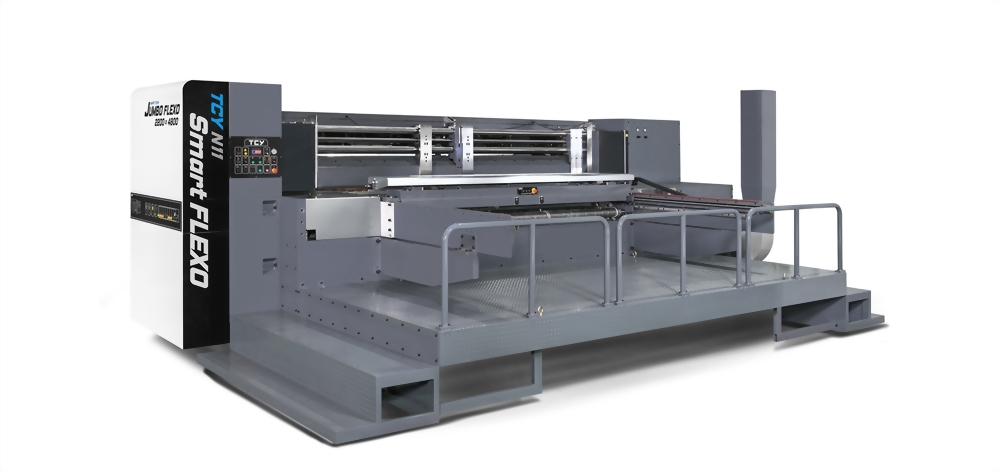

COUNTER EJECTOR

• Full integrated construction via HMI control panel.

• Quick positioning via AC servo motor drive.

• Full closed unit for safety operation.

• Top loading device for receiving and stacking boxes.

• Suitable for die cutting box use.

• Adjustable box insert inclined angle and loading area.

• Accurate counting quantity of boxes and eject bundle of boxes.

• Upper holding belt to deliver bundle of boxes without collapse.

• Separate operation control panel.

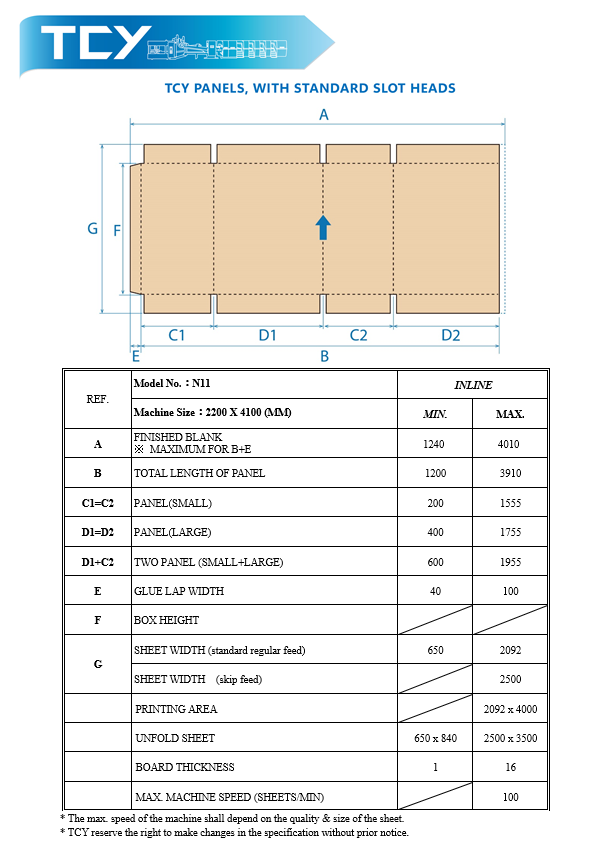

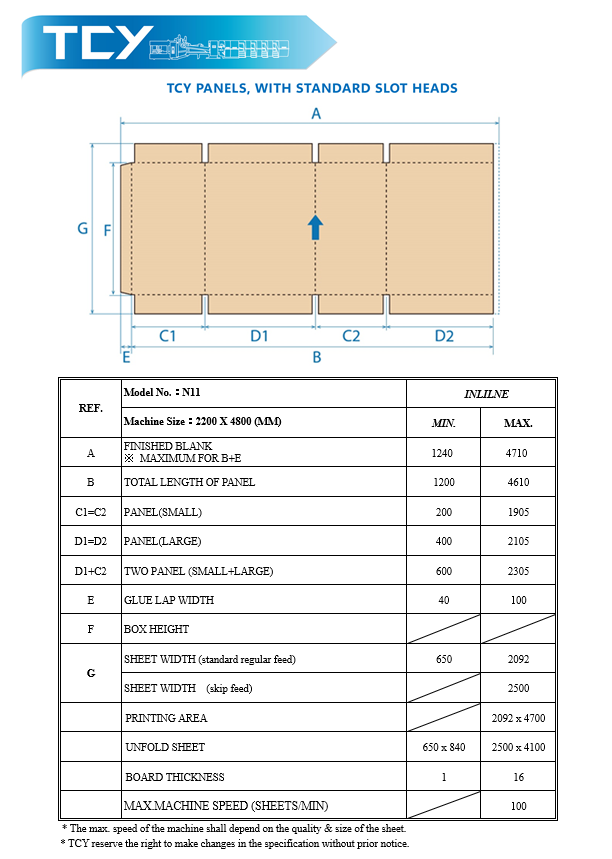

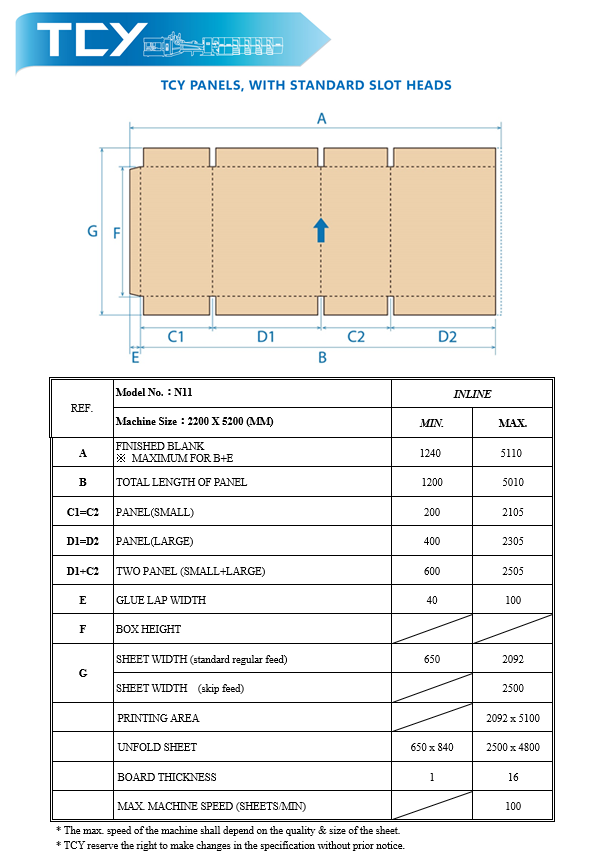

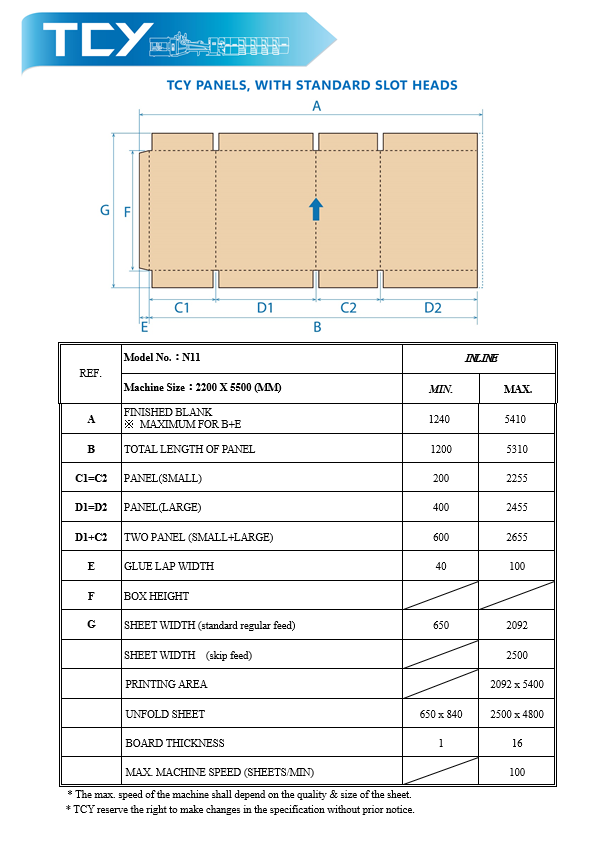

★TCY PANELS, WITH STANDARD SLOT HEADS